Jun 20th 2024

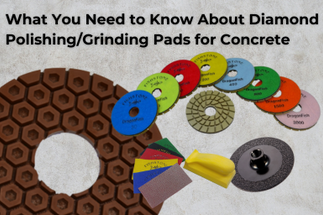

What You Need to Know About Diamond Polishing/Grinding Pads for Concrete

When searching for the best polishing pad for concrete, there are several key factors to consider. The quality of the pad can greatly impact the efficiency and outcome of your project. Here are the top considerations:

1. Diamond Quality

2. Matrix

3. RPMs of the Polisher

4. Wet or Dry Polishing

5. Material Being Polished

While all these factors are important, the two most critical aspects are the matrix and the quality and number of diamonds in the pad.

Diamond Quality

Diamond polishing pads and other diamond concrete tools use synthetic industrial-grade diamonds. These diamonds are graded on a three-tier system: good, better, and best.

- Top-Tier Diamonds: The highest quality and most expensive diamonds have the least number of fractures and the best size and shape for cutting. Fewer fractures mean the diamonds are less likely to shatter and fall out of the matrix, ensuring the pad lasts longer. These diamonds stay in the matrix until they are completely worn out, rather than falling out prematurely.

- Diamond Grit The grit of a diamond pad is determined by the size of the diamonds used. Higher grit pads use smaller diamonds, while lower grit pads use larger diamonds. This is why lower grit pads can sometimes be more expensive. Manufacturers blend diamond powder with a matrix to hold the diamonds in suspension. Consistent diamond sizing is crucial for effective polishing.

Cheap and super-cheap pads often contain fewer and lower-quality diamonds. These inexpensive options, commonly found on sites like Amazon, do not offer the durability and performance of higher-quality pads.

Matrix

The matrix is the material that holds the diamonds in place. For concrete, especially concrete less than 28 days old, a very hard matrix is essential.

- Concrete vs. Granite Most polishing pads sold for concrete countertops today are actually designed for granite or marble. These pads wear away much faster on concrete. For effective concrete polishing, the matrix must be hard enough to withstand the abrasive nature of concrete. Conversely, granite requires a softer matrix.

- Matrix Wear Rate The goal is to have a matrix that wears away at a rate that consistently exposes fresh diamonds. Using a concrete pad on granite results in minimal wear and insufficient diamond exposure. Conversely, using a granite pad on concrete causes the matrix to wear away too quickly, reducing the pad's useful life.

Other Considerations

- RPMs of the Polisher: Different pads are designed to operate optimally at different rotational speeds. Ensure your polisher’s RPM matches the pad’s recommended speed for best results.

- Wet or Dry Polishing: Some pads are designed specifically for wet polishing, which helps to cool the pad and reduce dust. Others are designed for dry polishing. Ensure you choose the right type for your project.

- Material Being Polished: Different materials require different pads. Always choose a pad specifically designed for the material you are working with.

Conclusion

When choosing diamond polishing pads for concrete, focus on the quality of the diamonds and the matrix. Avoid pads designed for granite or marble, as they will not provide the same durability and efficiency on concrete. For reliable pads, consider products from Fishstone (https://www.concretecountertopsupply.com), which are specifically designed for concrete and tested for optimal performance.

By understanding these factors and selecting the right pad, you can ensure a more efficient and effective polishing process for your concrete projects.